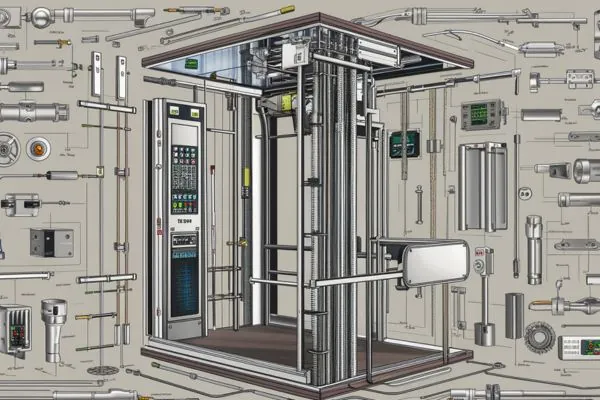

WHAT ARE THE PARTS OF AN ELEVATOR?

Elevators are complex systems with many critical components working together to ensure smooth and safe vertical transportation. There are several parts, and it will depend on the type of elevator traction, hydraulic and escalator, which also have different types of traction and hydraulic elevators. Some essential parts include:

Controller Assembly

This acts as the elevator’s brain, managing the elevator’s movement and operation based on inputs from the car and hall calls.

Machine Assembly

This includes the motor/machine and the drive that powers the elevator’s movement

Cable Systems

The steel ropes attached to the car and the counterweight system raise and lower the elevator car.

Car Assembly

This includes the cabin where passengers ride, its operating panel, lights, and doors.

Safety Systems

Including brakes, safety interlocks, buffers, emergency signaling devices, braking systems, governors, and many more.

Guide Rails and Shoes

These help keep the elevator car aligned on the rails as the car moves up and down the shaft.

Door Mechanisms

To prevent doors from closing on passengers, the doors themselves, the door operator, the opening and closing mechanisms, and the safety sensors should be involved.

WHY IS ELEVATOR MAINTENANCE IMPORTANT?

An elevator should receive routine maintenance just as your car does; missing maintenance takes a toll on it. Elevator maintenance is vital for several reasons:

Safety

Regular maintenance ensures all safety mechanisms are functioning correctly to protect passengers. Most areas have an authority having jurisdiction that ensures elevators are inspected.

Reliability

Elevators must comply with various safety codes and standards; maintenance ensures these requirements are met. The authority having jurisdiction helps enforce compliance and safety.

Compliance

Elevators must comply with various safety codes and standards; maintenance ensures these requirements are met. The authority having jurisdiction helps enforce compliance and safety.

Cost-efficiency

Routine maintenance can prevent costly repairs and replacements from a poorly maintained system. Elevator repair costs are rising in buildings with elevators.

Longevity

Regular servicing prolongs the life of elevator components and the system. An elevator is one of the most expensive assets of a building; maintaining its life cycle is essential for many reasons.

Read more related articles:

WHY DO ELEVATORS FAIL SO OFTEN?

Frequent elevator failures can often be attributed to several factors:

Wear and Tear

Elevators are mechanical systems subject to wear and tear from daily use. Parts like cables, pulleys, and brakes can degrade over time. Life just happens, and the elevator becomes old and worn out.

Poor Maintenance

Inadequate or infrequent maintenance can lead to premature system failures. Regular maintenance can identify and rectify minor issues before they become significant problems.

Aging Technology

Older elevators may not operate as efficiently as newer models, requiring more frequent repairs or total system overhauls. As newer technology evolves and parts need replacing, it may become difficult to make parts work together.

Inconsistent Use

Elevators in buildings with high traffic volumes or irregular use may experience more breakdowns due to the erratic strain on their systems. Elevators need to be used for what they are installed for. It is common to see elevators overloaded or designed for people moving criteria that change as the building’s use changes.

Design Flaws and Installation Errors

Sometimes, the initial design and installation may contribute to ongoing operational challenges. For example, some elevators have been designed badly, resulting in a shorter life cycle.

WHEN IT COMES TO REPLACING PARTS, BUILDING MANAGERS HAVE SEVERAL OPTIONS

OEM Parts

Original Equipment Manufacturer parts are typically recommended for best performance and compatibility but can be more expensive.

Read more related article:

Aftermarket Parts

These parts are generally cheaper and can be high-quality, but they might not always match the exact specifications of OEM parts.

Refurbished Parts

Used parts restored to functional condition can be a cost-effective solution, especially for older models for which parts may no longer be readily available.

Custom Fabricated Parts

Sometimes, parts must be custom-made, particularly for very old or unique elevators, which can be expensive and time-consuming.

Choosing the correct type of replacement parts involves considering the elevator’s age, usage, and the specific performance requirements of the building. Consulting with professional elevator consultants can help make informed decisions that balance cost, compliance, and performance.

Have a Question About Elevators?

FAQ for Guidelines for Elevator Replacement Parts

What are the most commonly replaced parts in an elevator?

This question helps users understand which components they might need to consider more frequently for checks and replacement. This is really hard to say due to the many applications of elevator usage.

How often should elevator maintenance be performed?

Elevator maintenance should typically be performed monthly; however, it is common to see quarter maintenance. The frequency can vary based on the elevator’s age, usage, and manufacturer recommendations.

What are the signs that an elevator needs immediate repair or replacement of parts?

AccordioSigns include unusual noises, jerky rides, delayed start, frequent breakdowns, or doors not opening or closing properly; these can also mean the elevator need maintenance as well. Any operational irregularity is a cue to consult a professional.n Content

Can I use aftermarket parts for my elevator, or should I stick to OEM parts?

It really depends on the parts; you should consult a professional elevator consultant who understands the industry and is not trying to sell you parts.

What is the typical lifespan of an elevator’s major components?

Major components can last up to 20 years, depending on usage and maintenance. However, there are several components that need replacement or upgrades more frequently.

How does regular maintenance impact the safety and efficiency of an elevator?

AccordRegular maintenance ensures all elevator components function correctly, reducing the risk of problems and breakdowns. It also enhances efficiency by preventing minor issues from developing into major problems.ion Content